Can your supply chain adapt to unforeseen events?

Leverage AI Simulation to Enhance your Supply Chain Planning

Discover the power of Cosmo Tech's AI-Simulation platform, designed to build agile and resilient supply chains that thrive amidst uncertainty. Compatible with SAP IBP, Kinaxis, Blue Yonder, OMP

By seamlessly integrating AI Simulation into your existing Advanced Planning and Scheduling (APS) software, you'll gain comprehensive visibility into your entire value chain, identify key vulnerabilities, and make informed decisions with optimal risk analysis. Our solution excels at accounting for uncertainties in the current business environment, such as demand fluctuations, market dynamics, and potential supply chain disruptions.

Compatible with SAP IBP, Kinaxis, Blue Yonder and OMP, our innovative tool empowers you to navigate supply chain complexities in an unpredictable market with confidence.

.png?width=450&height=276&name=Untitled%20design%20(45).png)

Extend supply chain capabilities and build resilience in the face of uncertainty

Create a dynamic Simulation Twin of the entire supply chain, simulate thousands of “what-if” scenarios, and incorporate uncertainty into your planning.

- Pinpoint supply chain vulnerabilities and use powerful optimization algorithms to mitigate risks

- Gain a comprehensive view of all potential outcomes and understand how uncertainties affect the overall company performance

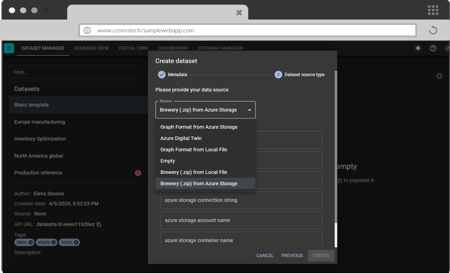

Build integrations the way you want it

While there are several pre-built connectors available, users can also leverage custom function-based connectors that give freedom to support tailored scenarios.

- Align data and information with tailored requirements, workflows and processes

- Extend functionalities of both AI Simulation and APS software

- Ensure scalability to accommodate evolving business needs

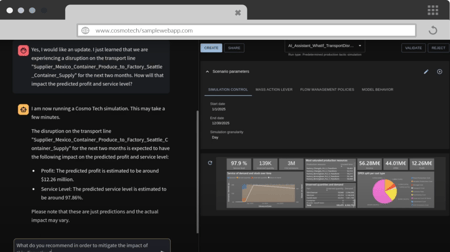

Leverage our Copilot to enhance decision-making

Leverage our state-of-the-art virtual assistant that integrates Generative AI (GenAI) with simulation capabilities. With an intuitive interface, managers can effortlessly model disruptions, explore "what-if" scenarios, and align strategies with business goals.

Our simulation engine evaluates thousands of possibilities to deliver the most effective options, providing reliable, expert-validated insights and recommendations.

Case Studies

Discover how leading companies from manufacturing and automotive sectors rely on Cosmo Tech's combined predictive and prescriptive capabilities to anticipate what's coming and confidently optimize operations, improve profitability, build resilience and sustainability.

How a global automotive supplier used AI Simulation to reduce its inventory levels while maintaining customer satisfaction.

Challenge

Faced with disruptions and unpredictable demand, the customer was struggling with rising buffer stock costs needed to maintain service levels. Relying on the Plant Master Scheduler's experience and intuition, which were largely based on past data, proved ineffective. This approach resulted in inaccurate demand forecasts, creating distrust and making it difficult to anticipate and adjust plans effectively.

Solution

Cosmo Tech offered a two-step solution to predict inventory and service levels over a 10-week period:

- Machine Learning: To determine the company’s demand uncertainty level.

- AI Simulation: To predict the impact of this uncertainty on key performance indicators (KPIs) and refine the demand forecasts. This step included scenario comparisons to identify the best balance between service levels and inventory.

Key Results

- Simulated results: up to 5% inventory level reduction

- Meeting customer demand for products while minimizing excess inventory

- Agile & informed decision-making to adapt to demand uncertainty and supply chain complexity

- Better performance management with new visibility into service rates and inventory costs

- Efficiency gains with a process standardization across 60 plants

How a major technology company optimized shipments and replenishment to cut costs.

Challenge

Our client, a large technology company, struggled with operational management due to uncertain demand and unforeseen events. Although they prefer cost-effective and eco-friendly shipping, last-minute orders and delays often force them to use expensive, high-pollution air transport. To balance this, they needed to simulate various scenarios to estimate fulfillment costs and determine the best replenishment policy.

Solution

Cosmo Tech Supply Chain solution allowed the customer to evaluate the best replenishment policies, minimizing total fulfillment costs while maintaining service levels.

Key features:

- What-if scenarios/simulations: simulation of different transport modes and stock policies

- Scenario comparison: comparison of the “Build-to-stock” simulation results with the Baseline scenario (Build-to-Order strategy).

- Inventory management optimizatio

Key Results

- -17% Air transport costs reduction

- $3M yearly savings opportunity

- Optimized inventory management & replenishment process

How an international tire manufacturer created an optimal sourcing strategy and an investment plan in the face of market uncertainty.

Challenge

Strategic sourcing was a significant challenge for our client, given its local-to-local manufacturing approach across 70 plants worldwide, operations in 170+ countries, and a diverse product range. Seeking a robust simulation solution, the client aimed to optimize sourcing strategies to improve profits, considering various key indicators like service levels, CO2 emissions, inventory, distribution, and plant capacity amidst a complex manufacturing and distribution network.

Solution

Cosmo Tech’s AI-Simulation Technology created a detailed Prescriptive Simulation Twin, enabling the client to model and simulate 80,000 scenarios with over 3,000 dynamic variables. This allowed our client to evaluate different sourcing strategies and predict the impact on key performance indicators.

Key Results

- Development of a 5-year strategic sourcing plan aimed at reducing annual logistics costs by €10m.

- Optimized global profit margin by over 5%.

- Decreased transport and customs costs by more than 60%.

- Achieved significant reductions in immobilized transportation costs.

Michelin North America, Inc selected Cosmo Tech for Supply Chain Simulation

“By partnering with experts in AI and Supply Chain Simulation like Cosmo Tech, we’re able to accelerate our transformation, adopting a more agile approach in our supply chain and business.”

George Kurian, VP of Supply Chain and logistics at Michelin North America, Inc.

.png)

Key Features

Unlimited what-if scenarios

Design & simulate scenarios to predict the impact of your decisions on your whole organization

How-to optimization

Prescribe the best operational strategy for your supply chain at any time scale and supporting your KPIs

Sensitivity analysis

Test robustness to unexpected events to mitigate risks and improve your production plan

Risk impact assessment

Use risk simulation to anticipate potential cascading and bullwhip effects of several risks impacting your performance

Cost calculation

Consider the costs of your scenarios and develop a realistic production plan to minimize these costs

Seamless integration

Easily connect to APS solution you use like Kinaxis, Blue Yonder, OMP, SAP IBP.

Learning Center

Embrace Supply Chain Uncertainty with AI Simulation

Download this ebook to delve into the transformative capabilities of AI simulation for a resilient supply chain. Explore how major manufacturing companies used this technology to run thousands of ‘what-if' scenarios to spot potential disruptions and crafted optimal plans that resulted in millions of dollars in savings.

-1.webp)

About Cosmo Tech

Cosmo Tech is an AI-Simulation Software company and an expert in prescriptive AI Simulation and Enterprise Digital Twins. Leading companies from the manufacturing, automotive, energy, and transport rely on Cosmo Tech’s combined predictive and prescriptive capabilities to anticipate what’s coming and confidently optimize operations, improve profitability, build resilience and sustainability.